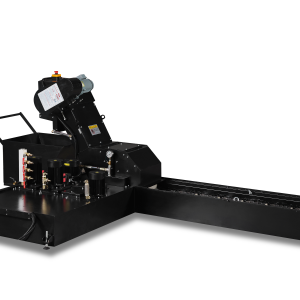

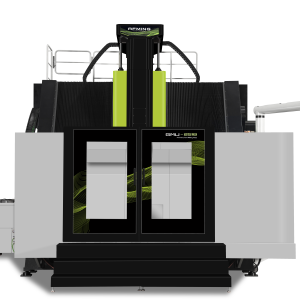

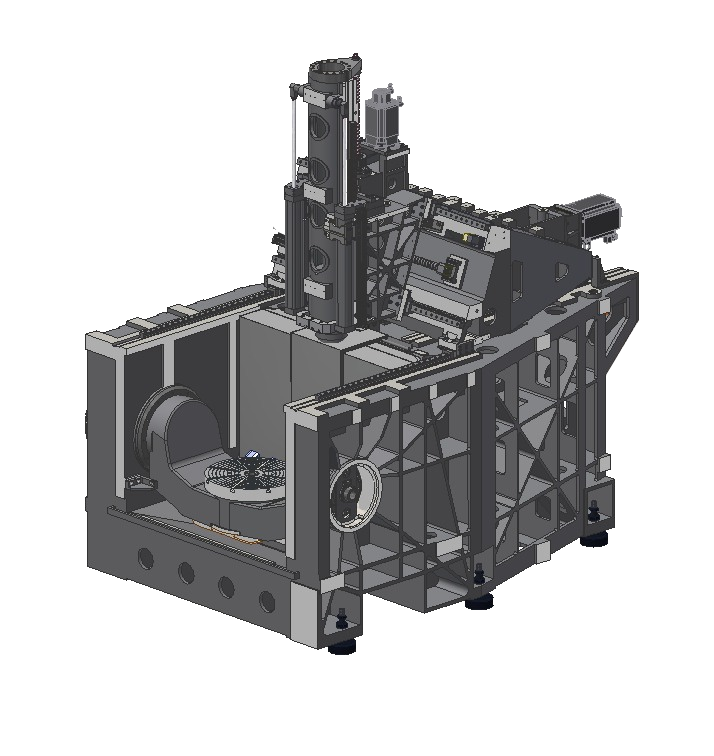

How about our 5 axis CNC Machining Center GMU-600 ?

GMU600 series is a overhead gantry crane 5 axis CNC machining center, and its A axis adopts precise backlash reduction of gear drive, which has higher output torque and stronger torsional rigidityits than torque motor drive. C-axis torque motor direct-drive dynamic response and rotary precision are both excellent.

GMU-600 5 axis CNC Machining Center Advantage:

The new generation of GMU600 5 axis CNC machining center can meet the high-efficiency and flexible processing requirements of precision parts. and it can “fast, stable and accurate “realize precise and efficient processing of precision parts. It is widely used in precision machining fields such as the automobile, industrial equipment, and mold industries.

1, High rigid bed structure

GMU600 overhead gantry crane 5 axis CNC machining center places the three-axis motion on the base. Stay away from the cutting area. The integrated base has high overall rigidity. The cradle turntable is supported on the base, the force flow is short, and the carrying capacity is high. Z axis is high response pressure balance, effectively reduce the dynamic load of the thread, reduce the temperature rise, extend the life of the screw. The Y-axis is supported by four 35mm high-rigidity roller guides for excellent dynamic performance and accuracy retention.

- GMU600 adopts crane gantry structure design is stable and reliable

- Machining table diameter 500mm, maximum loading 800mm

- X/Y/Z rapid displacement up to 40m/min

- Maximum cutting feed rate 20m/min

- X/Y/Z axis high response screw rotating ball screw drive, effectively inhibit thermal elongation, high accuracy and stability.

- Axis A is DIN5 high precision gear drive, static torque 3500Nm

- Axis C is DD motor direct drive or gear drive,

- Standard Heidehan linear grating ruler, X/Y/Z axis positioning accuracy 0.006/0.006/0.005mm, A/C axis standard Heidehan circular grating positioning accuracy 5 Angle seconds

- Tool measuring device (optional)

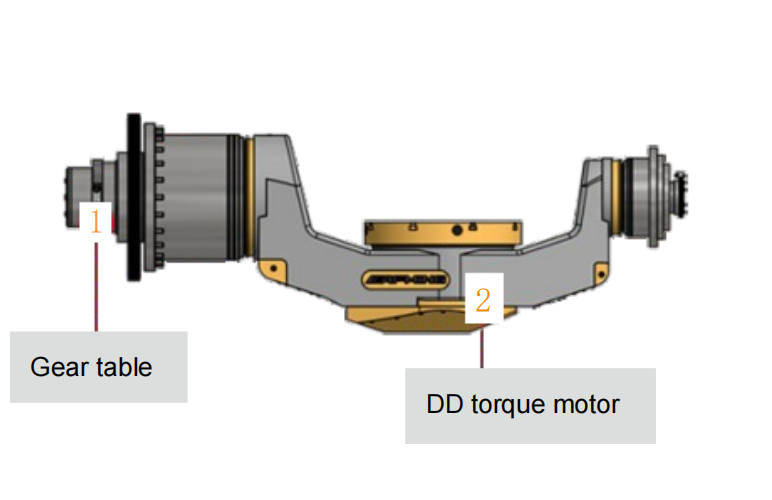

2, The perfect combination of high rigidity and high dynamic

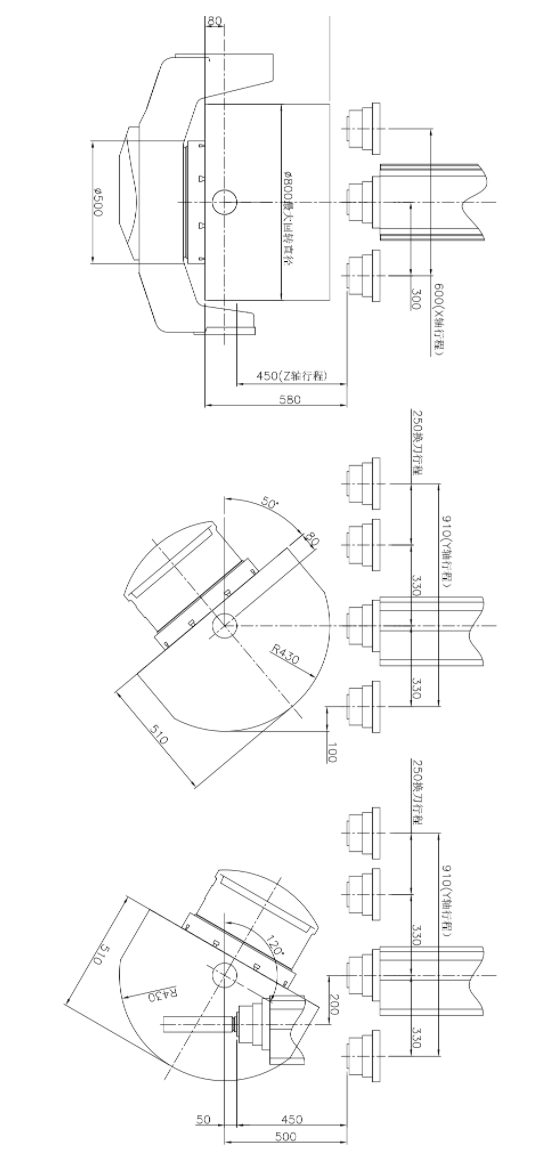

Precision anti-backlash gear drives GMU600 cradle rotary table A shaft, which has higher output torque and stronger torsional rigidity than conventional torque motor. When the load changes, the stability of electromechanical servo system is better; C axis adopts torque motor direct drive, dynamic response and rotation accuracy are excellent.

GTRT gear drive turntable

- A axis: servo motor + helical gear(two-stage anti-backlash technology patent)

- C axis: torque motor(high-speed response)

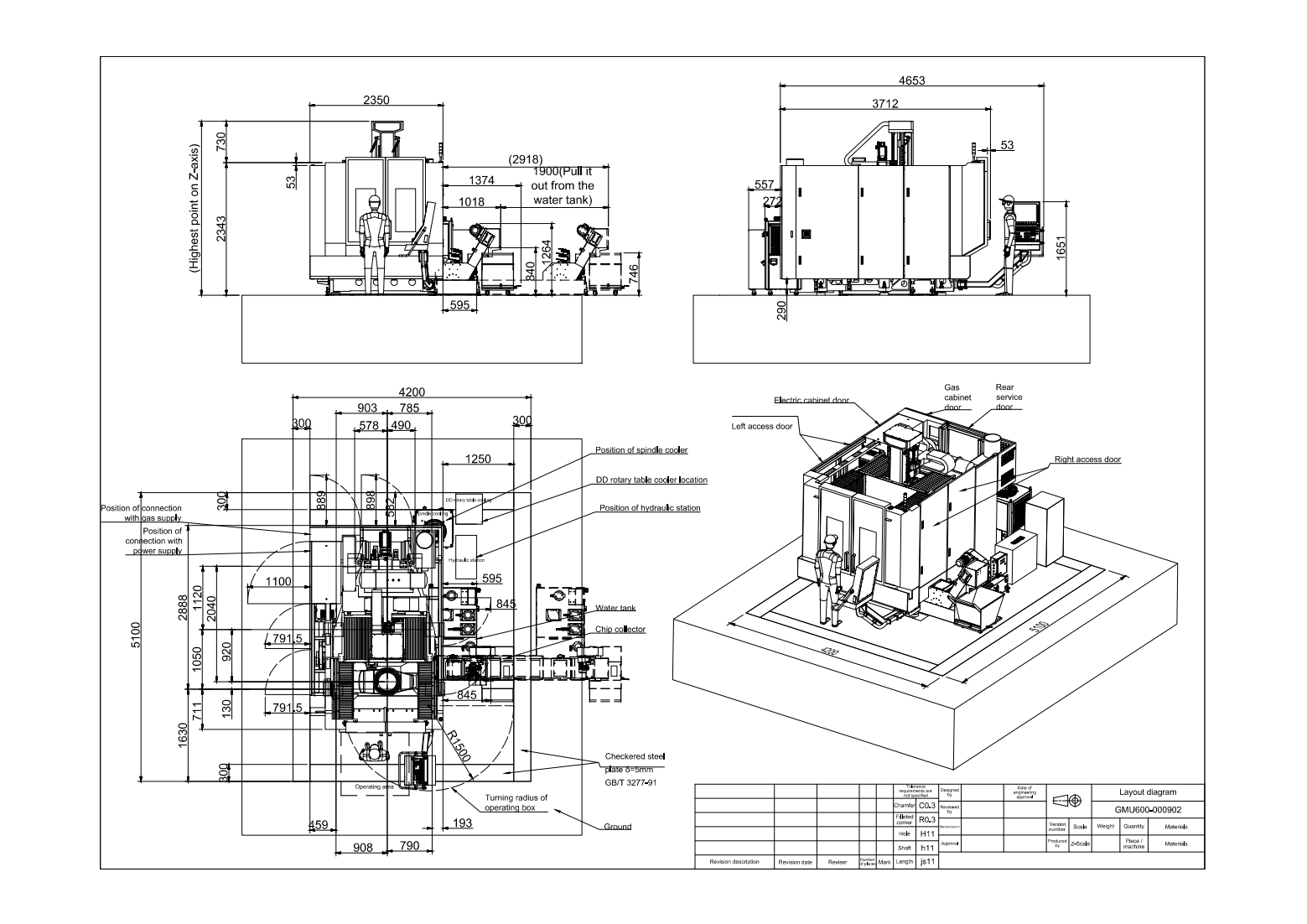

| X/Y/Z stroke: | 600/910(including tool change stroke)/450 |

| A/C stroke: | ±120°/360° |

| Distance from table to spindle nose: | 120-570mm |

| Worktable size: | Φ500mm |

| X/Y/Z fast displacement : | 40/40/40m/min |

| Maximum cutting feed rate : | 20m/min |

| Machine size : | 5210x3724mm² |

| Maximum load : | 300kg |

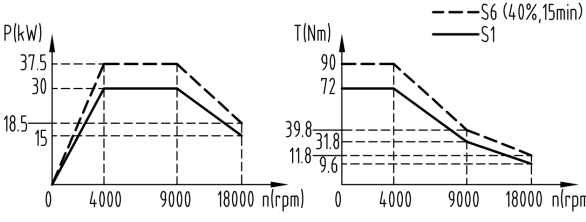

3, Super Power Motorized Spindle

Configure the 18000rpm AFMING spindle. Fully consider parts processing, mold processing and other special processing conditions, to provide customers with tailor-made spindle solutions, expand the processing range, improve processing efficiency.

Internal cycle cooling: Motor cooling&Bearing cooling

With internal circulation cooling, effectively solve the temperature difference between the inner and outer rings of the bearing, and achieve high rigidity and precision of high-speed operation of the spindle.

Features

- Low rotor temperature rise: The whole rotor of the main shaft, including the iron core of the motor rotor, is cooled by internal circulation to achieve low temperature rise.

- The thermal elongation of the spindle is small: The temperature rise of the spindle rotor is low, and the thermal deformation of the material is small.

- The thermal stability time of the main shaft is short: The internal circulation cooling of the spindle can quickly reach the state of thermal balance

- Spindle rigidity: Bearing temperature rise is low, the same speed can be applied to larger size bearings and larger preload, improve rigidity

- Spindle limit speed is high: Bearing temperature rise is low, the same specification bearing can achieve higher speed operation

- Low bearing temperature rise: When the bearing is cooled, the bearing temperature rise is low and the lubrication life is long

18000rpm electric spindle HSK-A63: Suitable for high finish surface processing

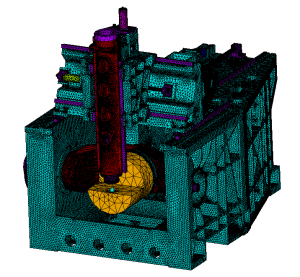

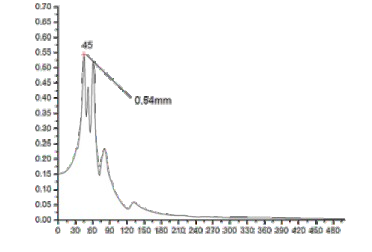

4, Using finite element analysis and dynamic optimization, engineers greatly improve the performance of the whole machine.

During the design, engineers use FEA for dynamic optimization to achieve the best match of the structure quality, stiffness, and damping of the whole machine, reducing the cross dynamic flexibility between the tool tip and the workpiece, improving the regeneration flutter limit during rough machining, enhancing the cutting amount of rough machining, and achieving the purpose of efficient cutting. At the same time, engineers reduce the relative amplitude between the tool tip and the workpiece, improving the surface finish during processing, decreasing the vibration speed of the tool tip, and reducing tool wear.

- Dynamic optimization through FEA, effectively improve the anti- vibration of the whole machine

- Accurately calculate the optimal dynamic rigidity under actual working conditions

- Improve the natural frequency and cutoff frequency of the feed drive system, effectively reduce the positioning time and the lag of the feed system, and achieve highly responsive dynamic performance and high-speed machining profile accuracy

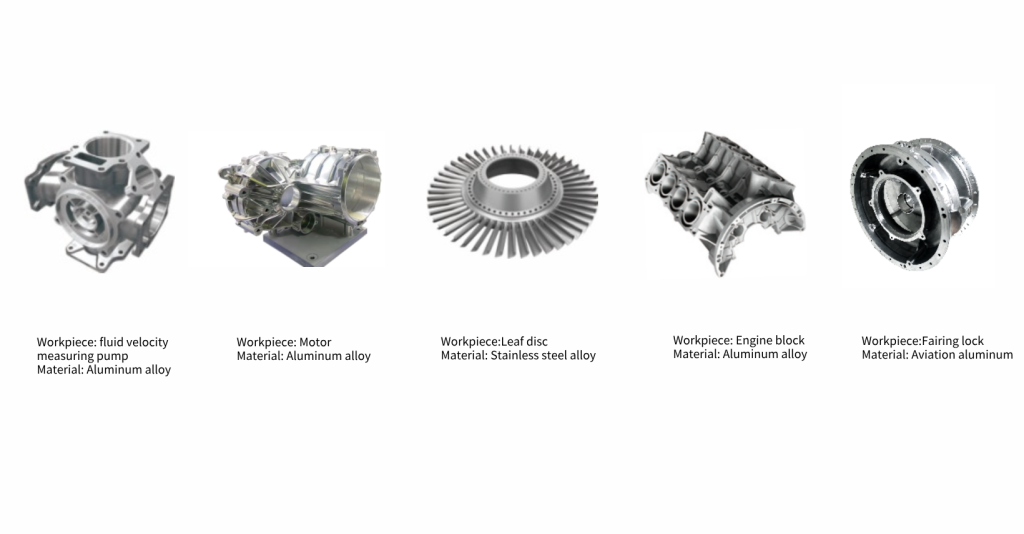

Afming 5 axis CNC Machining Center GMU-600 Application

Application field | + Automotive industry + Civil aviation industry + Industrial equipment + Mold industry

GMU600 Specification

| Items | Unit | GMU-600E | GMU-65 | |

| System | System | Heidenhain iTNC 620 | Heidenhain iTNC 620 | |

| Worktable | X/Y/Z axis travel | mm | 650/950/500(Y axis travel includes tool change travel) | 650/950/500(Y axis travel includes tool change travel) |

| A/C axis travel | degree | ±120/360 (infinite) | ±120/360 (infinite) | |

| Distance from spindle nose to table surface | mm | 140-640 | 140-640 | |

| Worktable size/max payload | Mm | φ500 | φ630 | |

| kg | 0°:400 90°:300 |

300 | ||

| Spindle | Spindle speed /Taper handle | rpm | 18000/HSK-A63 | 18000/HSK-A63 |

| Power(S1/S6-40%) | kW | 30/37.5 | 30/37.5 | |

| Output torque (S1/S6-40%) | Nm | 72/90 | 105/130.6 | |

| Feed system | X/Y/Z axis rapid feed | m/min | 40/40/30 | 40/40/30 |

| Cutting feed speed | m/min | 20 | 20 | |

| A/C axis rapid feed | rpm | 20/30 | 20/80 | |

| Positioning precision ISO 10791-4:1998 |

X/Y/Z | mm | 0.008/0.008/0.007 | 0.008/0.008/0.007 |

| A/C | ARC” | 8/8 | 8/8 | |

| Repeated positioning precision ISO 10791-4:1998 |

X/Y/Z | mm | 0.005/0.005/0.004 | 0.005/0.005/0.004 |

| A/C | ARC” | 4/4 | 4/4 | |

| Automatic tool change system |

Tool number | pcs | 48T | 48T |

| Tool change time(tool-tool) | sec | 7(may vary per spindle unclamping) |

7(may vary per spindle unclamping) |

|

| Tool max length | mm | 250 | 250 | |

| Tool max diameter/adjacent no tool | mm | φ80/中120 | φ80/φ120 | |

| Tool max weight | kg | 8 | 8 | |

| Overall size | Total height | mm | 3,450 | 3,300 |

| Footprint (length×width) | mm² | 5100×4200 | 5100×4200 | |

| Net weight | Kg | about 13,500 | about 13,500 | |

| Power demand | kw | 57 | 57 | |

GMU600 Standard/Optional Configuration

| No. | Standard configuration | |

| 1 | System | Heidenhain iTNC 620 |

| 2 | sheet metal | Capping full enclosure body sheet metal(including water tank) |

| 3 | Spindle | HSK-A63-18000RPM AFMING Electric spindle |

| 4 | A/C Cradle turntable | GMU600E: Gear rotation structure (imported DIN5 grade grinding gear) |

| Spindle cooler | GMU65: A-axis precision gear drive/C-axis DD direct drive cradle turntable | |

| 5 | Spindle cooler | Water cooler(China) |

| 6 | Tool setting instrument | Marposs contact |

| 7 | 3 axis linear grating | HEIDENHAIN |

| 8 | AC axis circular grating | HEIDENHAIN |

| 9 | Tool magazine | HSK-A63-48T flat tool magazine |

| 10 | Chip removal system | Scraper chip conveyor |

| 11 | guide | X-axis 35 roller guide,Y-axis 45 roller guide,z-axis 35 Guide |

| 12 | Screw rod | Xaxis r40x20,Y axis r50x20,Z axis r40x16 |

| 13 | Z-axis balance system | Air pressure balance system(Japan SMC) |

| 14 | Electric box thermostatic system | Constant temperature of air conditioner(Tongfei) |

| 15 | Pneumatic system | Japan SMC |

| 16 | Hydraulic station | Taiwan 7OCEAN |

| 17 | Automatic lubrication device | Grease type (Liubian,China) |

| 18 | Cleaning of processing area | Air gun and water gun for cleaning |

| 19 | Work light | LED light |

| 20 | Warning light | Three color warning light |

| 21 | Tool box and anchor screw | Tool box and anchor screw |

| 22 | Five axis center correction package | (including 3D probe)Heidenhain |

| 23 | Automatic ceiling components | GMU600-Automatic ceiling components |

| 24 | Oil mist collector | GMU600-QS-750(Qiushan Machinery) |

| 25 | Safety door lock | |

| No | Otional configuration | |

| 1 | System | Heidenhain iTNC 640 |

| 2 | Worktable size | 630mm |

| 3 | HSKA63-60T tool magazine | GMU600-230000 |

| 4 | Hexagon laser tool setter | GMU600-180001 |

| 5 | Blum laser tool setter | GMU600-180000 |

| 6 | CTS 30bar spindle center water outlet | |

| 7 | CTS 50bar spindle center water outlet | |

| 8 | CTS 70bar spindle center water outlet | |

| 9 | Automatic door | |

| 10 | Workbench ol pressure tooling port pipeline components (4 oil lines,1 airtight) |

Pipeline components of worktable oil pressure tooling port |

| 11 | Zero point positioning component of the turntable (3-way oil,2-way gas with airtightness) |

Zero point positioning component of turntable |

| 12 | Paper tape filtering component | Paper tape filtering component |